Understanding the Different Types of Printing Techniques

Introduction to Printing Techniques

Printing has been an essential part of communication and art for centuries. With the advancement of technology, various printing techniques have evolved, each offering unique benefits and applications. Understanding these methods can help you choose the most suitable one for your project or business needs.

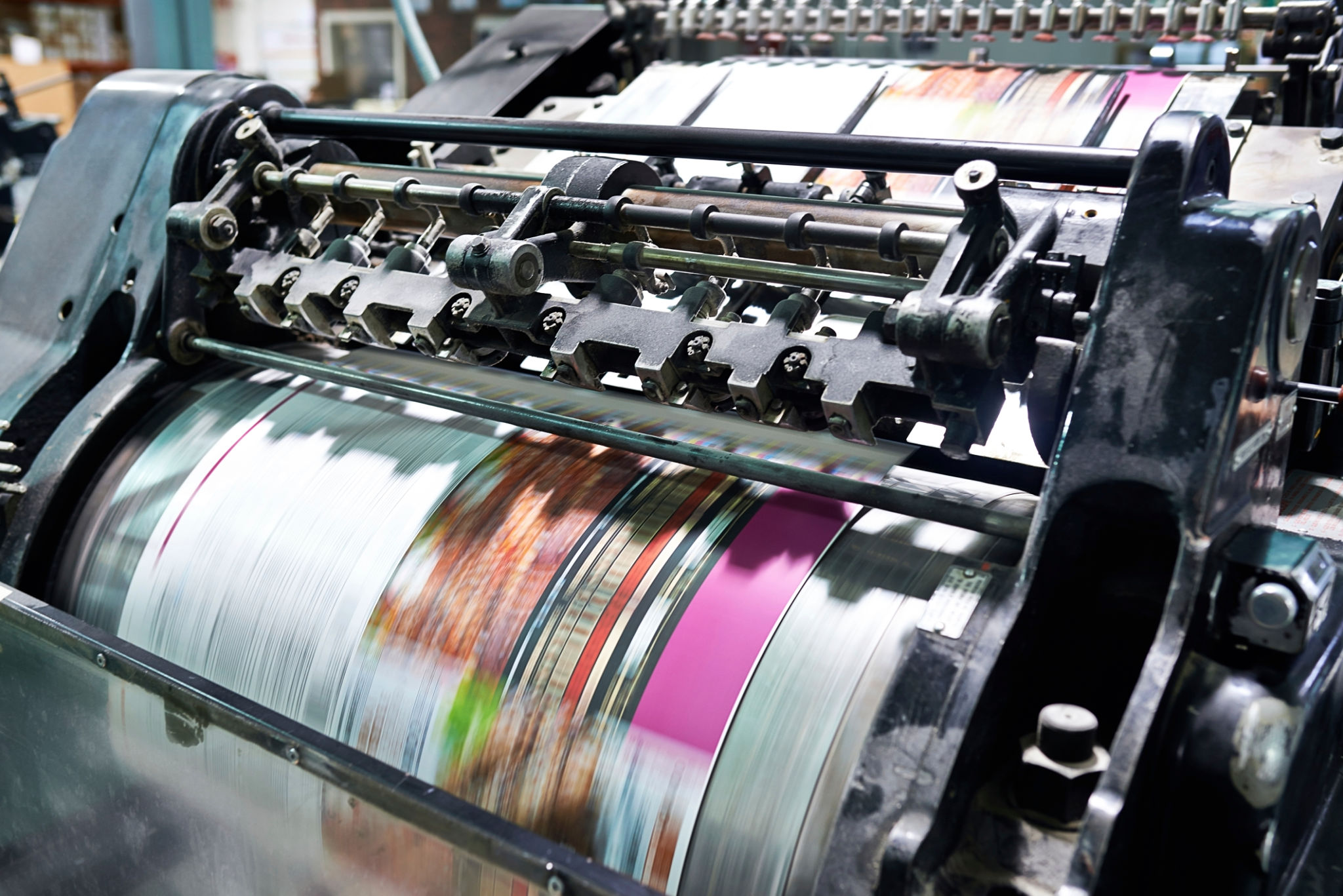

Offset Printing

Offset printing, also known as offset lithography, is one of the most commonly used printing techniques. It involves transferring an inked image from a plate to a rubber blanket, then onto the printing surface. This method is ideal for high-volume print jobs due to its cost-effectiveness and ability to produce high-quality images and consistent colors.

Advantages of Offset Printing

- High image quality: Offset printing produces sharp and clean images with excellent detail.

- Cost-effective for large volumes: The more you print, the cheaper the unit cost becomes.

- Versatility: It can print on various surfaces, including paper, cardboard, and plastic.

Digital Printing

Digital printing is a modern method that directly prints digital files onto various media. This technique eliminates the need for printing plates, making it a fast and flexible option for short runs and on-demand printing.

Benefits of Digital Printing

- Quick turnaround: With no setup time, digital printing is perfect for last-minute projects.

- Customization: Easily personalize prints without additional costs.

- Environmentally friendly: Reduces waste with minimal setup requirements.

Screen Printing

Screen printing is a popular technique for printing on textiles, ceramics, wood, and other materials. It involves pushing ink through a mesh screen onto the printing surface. This method is renowned for producing vibrant colors and is commonly used for T-shirts and posters.

Why Choose Screen Printing?

- Durability: Screen-printed items tend to last longer due to the thickness of the ink applied.

- Vivid colors: Ideal for bold designs with bright colors.

- Cost-effective for large quantities: Economical for bulk orders.

Flexography

Flexography is a versatile printing process used primarily for packaging and labels. It employs flexible relief plates and can print on almost any substrate, including plastic, foil, acetate film, brown paper, and more.

The Flexibility of Flexography

- High-speed production: Capable of producing large volumes quickly.

- Wide range of substrates: Can print on non-porous materials effectively.

- Sustainable ink options: Often uses water-based inks that are environmentally friendly.

Conclusion

The world of printing techniques offers a diverse range of options tailored to different needs and applications. Whether you require high-quality images for marketing materials or durable prints for clothing, understanding these methods empowers you to make informed decisions. By choosing the right technique, you can achieve optimal results that align with your project's goals and budget.